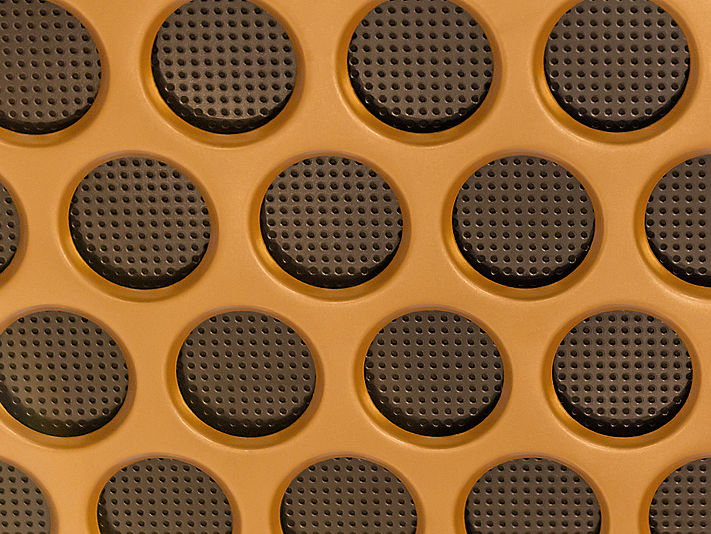

Enhancement of metal ceiling and metal wall cladding surfaces

The surface of metal ceilings and metal wall claddings can be enhanced and made more robust in a range of different ways. With powder coating, a single coat of ceiling and wall cladding surface enhancer is added to a metal such as steel or aluminium etc. With electrostatic powder coating, the metal part is charged positively while the powder particles are charged negatively, causing them to be attracted to the metal. Here, they are deposited uniformly on the surface of the ceiling. In an enamelling furnace, the powder is then melted to form a smooth, abrasion-resistant, uniform film.

The standard colour range from durlum consists of RAL 9010 matt and RAL 9016 matt. Of course all RAL colours are available on request.

When the ceiling surface is anodised, this involves aluminium that has been oxidised electrolytically. Once the aluminium has been pre-treated, anodisation takes place – usually in sulphuric acid, applying a DC current. This creates an oxide layer that is firmly bonded to the aluminium. This is therefore an oxidation process and not a coating of the ceiling surface. In a similar way to timber, the surface of the material is visible and is not concealed by a coating.

durlum can provide strip-anodised as well as part-anodised metal ceilings and metal wall claddings.

We shall be pleased to assist you in finding the perfectly matched form of enhancement for the surface of your ceiling.

Find general information on this topic in our metal ceiling catalogue.

Click here to download the suitable chapter „Surface finish“.